A conventional engine lathe or a turret lathe is a common machine in just about every machine shop. A lathe is used for machining cylindrical or conical work, such as shafts, rings, wheels, bores, threads, etc. The most common lathe operation is removal of material from a round stock, using a turning tool for external cutting. A lathe can also be used for internal operations such as boring, as well as for grooving, threading, etc., if a proper cutting tool is used. Turret lathes are usually weaker in machining power than engine lathes, but they do have a special carousel that holds several mounted cutting tools. An engine lathe has often only one or two cutting tools mounted at a time, but has more machining power.

Typical configuration of a two axis slant bed CNC lathe - rear type

Typical configuration of a CNC lathe with two turrets

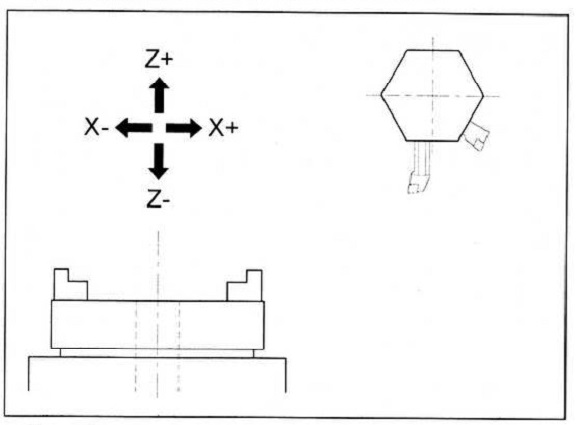

Schematic representation of a vertical CNC lathe

This is true for both the front and rear lathes and for lathes with three or more axes. The chuck face is oriented vertically to the horizontal spindle center line for all horizontal lathes. Vertical lathes, due to their design, are rotated by 90°, where the chuck face is oriented horizontally to the vertical spindle center line. In addition to the X and Z primary axes, the multi-axis lathes have individual descriptions of each additional axis, for example, the C axis is usually the third axis, used for milling operations, using so called live tooling.

- Two-axis Lathe

This is the most common type of CNC lathes. The workholding device, usually a chuck, is mounted on the left side of the machine (as viewed by the operator). The rear type,with the slant bed, is the most popular design for general work. For some special work, for example in the petroleum industry (where turning tube ends is a common work), a flat bed is usually more suitable. The cutting tools are held in a specially designed indexing turret that can hold four, six, eight, ten, twelve and more tools. Many such lathes also have two turrets.Advanced machine tool designs incorporate tool storage away from the work area, similar to the design of machining centers. Tens, even hundreds, of cutting tools may be stored and used for a single CNC program. Many lathes also incorporate a quick changing tooling system.

- Three-axis Lathe

Three-axis lathe is essentially a two-axis lathe with an additional axis. This axis has its own designation, usually as a C axis in absolute mode (H axis in incremental mode), and is fully programmable. Normally, the third axis is used for cross-milling operations, slot cutting, bolt circle holes drilling, hex faces, side faces, helical slots, etc. This axis can replace some simple operations on a milling machine, reducing the setup time for the job. Some limitations do apply to many models, for example, the milling or drilling operations can take place only at positions projecting from the tool center line to the spindle center line (within a machining plane), although others offer off-center adjustments.

The third axis has its own power source but the power rating is relatively lower when compared with the majority of machining centers. Another limitation may be the smallest increment of the third axis, particularly on the early three axis lathes. Smallest increment of one degree is certainly more useful than an increment of two or five degrees. Even better is an increment of 0.1°, 0.01°, and commonly 0.001°on the latest models. Usually the lathes with three axes offer a very fine radial increment that allows a simultaneous rotary motion. Those with low increment values are usually designed with an oriented spindle stop only.

• Four-axis Lathe

By design, a four-axis CNC lathe is a totally different concept than a three-axis lathe. As a matter of fact, to pro-gram a four-axis lathe is nothing more than programming two two-axis lathes at the same time.That may sound strange at first, until the principle of a four-axis CNC lathe becomes clearer.There are actually two controls (and two sets of the XZ axes),one for each pair (set) of axes. Only one program may be used to do the external or outside diameter roughing (OD) and another program to do the inside or internal roughing (ID). Since a four-axis lathe can work with each pair of axes independently, the OD and ID can be machined at the same time, doing two different operations simultaneously.The main keys to a successful 4-axis lathe programming is coordination of the tools and their operations, timing of the tool motions and a generous sense of healthy compromise. For several reasons, both pairs of axes cannot work all the time. Because of this restriction, special programming features such as synchronized waiting codes (typically Miscellaneous Function), the ability to estimate how much time each tool requires to complete each operation, etc., are required. There is a level of compromise here, because only one spindle speed can be used for both active cutting tools, although feed rate is independent for both pairs of axes. This means that some machining operations simply cannot be done simultaneously. Not every lathe job benefits from the 4-axis machining. There are cases when it is more costly to run a job on a 4-axis lathe inefficiently and it may be very efficient to run the same job on a 2-axis CNC lathe.

•Six-axis Lathe

Six-axis CNC lathes are specially designed lathes with a twin turret and a set of three axes per turret. This design incorporates many tool stations, many of them power driven, as well as back-machining capabilities. Programming these lathes is similar to programming a three-axis lathe twice. The control system automatically provides synchronization, when necessary. A small to medium size six-axis CNC lathe is popular choice of screw machine shops and industries with similar small parts and large volume applications.

VIDEO

Category: