♦ Zero Return for CNC Lathes

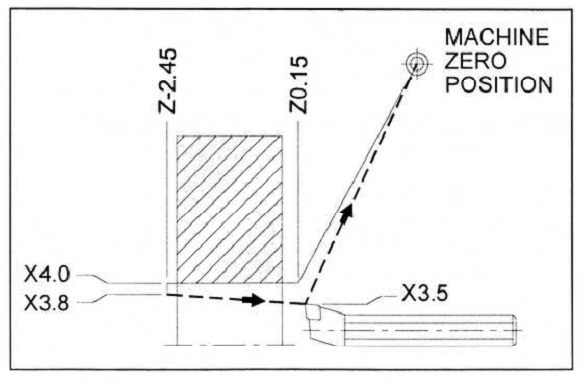

For CNC lathe work, the G28 command may also be used, usually for setup. Common application of the ma-chine zero return is also used, when at least one axis starts and ends at the machine zero position. This is quite often true of the X axis but not of the Z axis, which may be too far away on some larger lathe models.

Typically, a CNC lathe program will be designed in such a way, that machining of the first part will start from the machine zero, but any subsequent pail will be machined from a safe tool change position. This method is only prac-tical if the program uses geometry offset, rather than the older G50 setting. The most common method of machine zero return on the lathes is the direct method, without an in-termediate point, because no G91 is required, therefore, an error is more difficult to make:

N78 G28 UO

N79 G28 WO

These two blocks will return the cutting tool to the ma-chine zero in incremental mode, there is no intermediate motion applied. It is safer to move the X axis first, using the incremental mode U, then the Z axis, using the incremental mode W. If the work area is clear (watch for the tailstock), both X and Z axes can be returned to the machine zero at the same time:

N78 G28 UO WO

When using position register command G50, the XZ setting must always be known for this command. In this case, the programming rules for machine zero return are very similar. Assuming that the machine zero position is at the coordinate position X10.0 Z3.0, the program for the boring tool can be written in two ways - one without using the G28 command, the other one with the G28 command.

RETURN FROM MACHINE ZERO POINT

The preparatory command G29 is the exact opposite of G28 or G30 command. While G28 will automatically re-turn the cutting tool to machine zero position, G29 com-mand will return the tool to its original position - again, via an intermediate point.

In normal programming usage, the command G29 usu-ally follows G28 or G30 command. The rules relating to the absolute and incremental axis designation are valid for G29 in exactly the same respect as to the G28 and G30. All programmed axes are moved at the rapid traverse rate to the intermediate position first, defined by the preceding G28 or 030 command block. An example for a lathe application illustrates the concept:

(LATHE EXAMPLE)

• • •

T0303

• • •

G28 U5.0 W3.0

G29 U-4.0 W2.375

The G29 command should always be issued in the can-celed mode of both the cutter radius offset (G40) and the fixed cycles (G80), if either is employed in the program. Use the standard cancellation G codes - G40 to cancel cut-ter radius offset and G80 to cancel a fixed cycle, before the G29 command is issued in the program.

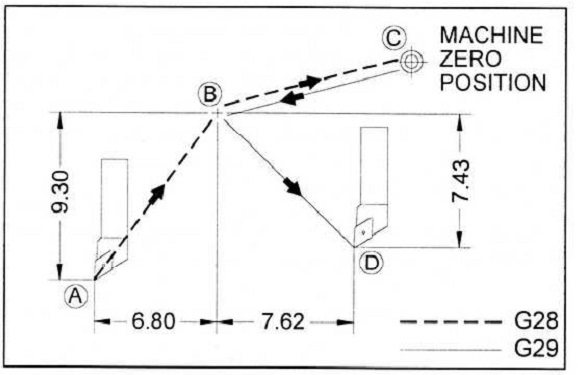

A schematic sketch of the tool motion is illustrated in Figure below

The illustration shows a tool motion from point A to point B first, then to point C, back to point B, and finally, to the point D. The point A is the starting point of the motion, point B is the intermediate point, point C is the machine zero reference point, and point ID is the final point to reach, the actual target position.

The equivalent program commands, starting at the cur-rent tool position, which is point A, and resulting in the A to B to C to B to D tool path are quite simple:

G28 U18.6 W6.8

......

G29 U-14.86 W7.62

Of course, there would be some appropriate action programmed between the two blocks, for example, a tool change or some other machine activity.

Similar to G27 command, there is only a weak support for G29 among CNC programmers. It is one of the commands that can be very useful in some rare cases, but virtually unnecessary for everyday work. However, it is always an advantage to know what 'tools of trade' are available in CNC programming. They may come handy.

RETURN TO SECONDARY MACHINE ZERO

In addition to the G28 machine zero command, specific CNC machines also have the G30 command. In this article, many examples apply equally to G28 and G30 commands and were sometimes identified as G28/G30 to cover both. So what is different in G30 and why is this command needed it in the first place?

By definition, G30 preparatory command is a machine zero return command to the secondary machine zero position. That position must be available on the machine at the time of purchase. Note the descriptive word is secondary, not second. In virtually all respects, G30 is identical to the G28, except that it refers to a secondary program zero.

This secondary program zero can be the physical second, third, or even fourth reference point, as specified by the ma-chine manufacturer. Not every CNC machine has a second-ary machine zero reference position, and not every CNC machine even needs one. This secondary machine reference point serves only some very special purposes, mainly for horizontal machining centers.

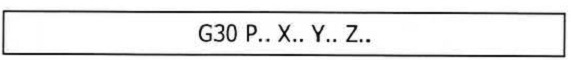

The programming format for G30 command is similar to the G28 command, with an addition of the P address:

where ... G30 =indicates the selection of a secondary reference position

P = can be P2, P3 and P4 to identify the secondary position (2-4)

XYZ = is the intermediate point definition (one axis minimum must be specified)

The most common use of a secondary machine zero reference point in CNC programming is for pallet changing. In the control unit parameter setting, the distance of the secondary reference point is set from the primary reference point and is not normally changed during the working life of the machine and the pallet changer.

To distinguish between multiple secondary machine zero positions, address P is added in the G30 block (there is no P address used for G28). If the CNC machine has only a sin-gle secondary machine reference position, the address P is usually not required in the program, and P1 is assumed in such a case:

G30 X.. Y..

is the same as

G30 P1 X.. Y..

In this case, the setting of the second reference point is within the parameters of the control system. In respect to other programming considerations, the G30 command is used in exactly the same way as the much more common G28 machine zero return command.

Pages

- « first

- ‹ previous

- 1

- 2

- 3

Category: