A machine unit equipped with a computerized numerical control system is commonly known as a CNC machine. In an analogy of the machine tool as the body of a CNC ma-chine system, the control unit is its brain, its nerve center. There are no levers, no knobs and no handles on a CNC machine the way they function on conventional milling machines and lathes. All the machine speeds, feeds, axes motions and hundreds of other tasks are programmed by a CNC programmer and controlled by a computer that is major part of the CNC unit. To make a program for a CNC ma-chine tool means to make a program for the control system. True, the machine tool is a major consideration as well, but it is the control unit that determines the format of the pro-gram, its structure and its syntax.

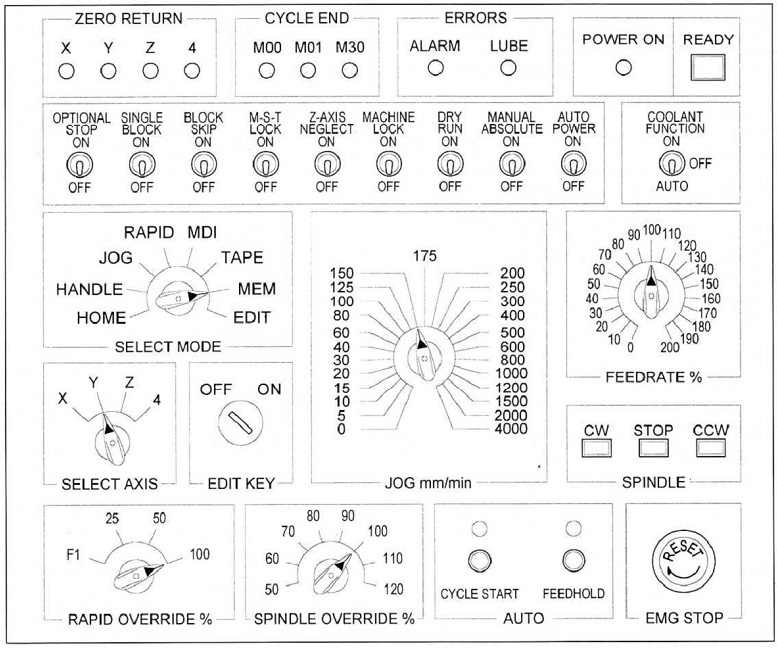

In order to fully understand the CNC programming pro-cess, it is important to understand not only the intricacies of how to machine a part, what tools to select, what speeds and feeds to use, how to setup the job and many other fea-tures. It is equally important to know how the computer, the CNC unit, actually works without the need to be an expert in electronics or a computer scientist. Figure shows an actual Fanuc control panel. The machine manufacturers add their own operation panel, with all the switches and button needed to operate the CNC machine and all its features. A typical operation panel is illustrated in second Figure. Another item required for the system, the handle, will be described as well.

Category: