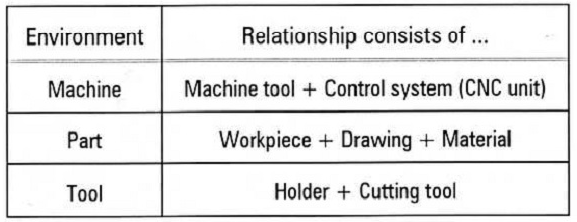

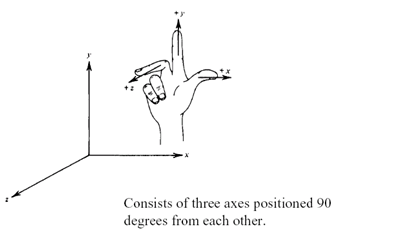

the basic relationship between the machine geometry and the part setup was discussed. CNC programmers work in a fairly precise environment, and mathematical relationships are of extreme importance.There are three major environments in programming that require an established mathematical relationship: