In order to shape metal by machine tools, the cutting tool should move in contact with the workpiece at certain specific points, while the workpiece or cutting tool is rotating.Coordinate system is required to define the movement on the machine.

CNC Lathe (turning) Machine’s coordinate system

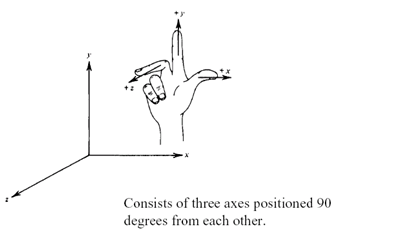

To ensure that the control system of the machine will read the specified coordinates correctly to indicate the position of the workpiece; the machine tool has its own "coordinate system“.All computer controlled machines are able to accurately and repeatedly control motion in various directions. Each of these directions of motion is called an axis. Depending on the machine type there are commonly two to five axes.Additionally, a CNC axis may be either a linear axis in which movement is in a straight line, or a rotary axis with motion following a circular path.

The following points are part of this system.

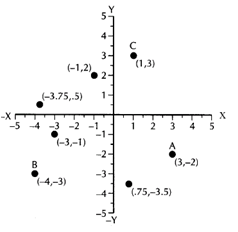

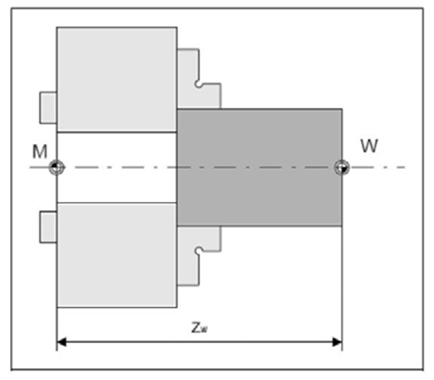

Dimensioning->To dimension the workpiece we need to specify a certain point on it, from which we should take the measurement. This point is the origin point.The origin point on the workpiece is called Workpiece zero point (W).

There are two types of Dimensioning

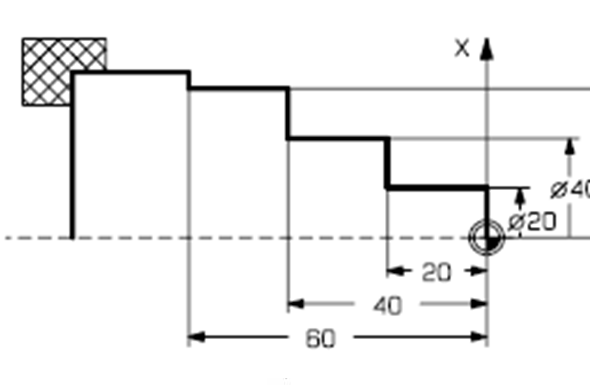

1)Absolute Dimension-All measurements are taken from the workpiece zero point See the Figure.

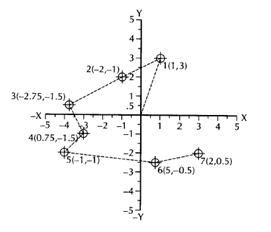

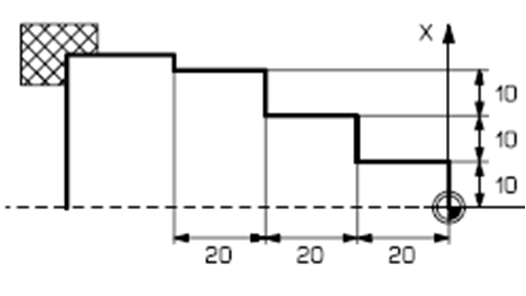

2)Incremental Dimension-Uses incremental values that are always measured from the current point to the next point.

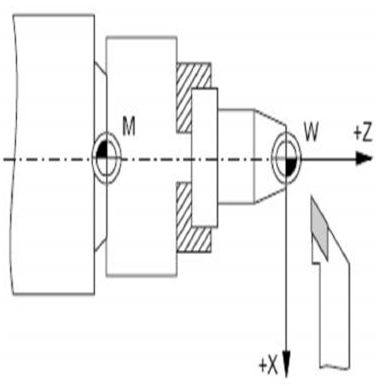

Turning Machine axes

CNC Turning machine has at least 2 controllable feed axes, marked as X and Z.When the cutting tool moves toward and backward the machine spindle, this is called movement along Z axis and When cutting tool moves in cross direction to the longitudinal axis of the workpiece, this is called movement along X axis.

->Positive Z direction is when the tool moves away from the workpiece in Z axis.

->Positive X direction is when the tool moves away from the work part in X axis.

VIDEO

Category: