Coordinate Geometry Basics

G - Code Programming G – Code Programming originally called the “Word Address” programming format. Processed one line at a time sequentially.

Reserved Code Words Worksheet

N – Sequence or line number

G – Preparatory function

Word Address 1

N – (Sequence or line number) A tag that identifies the beginning of a block of code. It is used by operators to locate specific lines of a program when entering data or verifying the program operation.

G – (Preparatory function) “G words” specify the mode in which the milling machine is to move along its programmed axes.

Word Address 2

Dimension Words: - X – Distance or position in X direction

Y – Distance or position in Y direction

Z – Distance or position in Z direction

M – Miscellaneous functions M words specify CNC machine functions not related to dimensions or axial movements.

Word Address 3

F – Feed rate (inches/minute or millimeters/ minute) “Rate at which cutting tool moves along an axis.”

S – Spindle speed (rpm – revolutions per minute) “Controls spindle rotation speed.”

T – Tool number (Specifies tool to be selected.)

Word Address 4

I – Circular cutting reference for x axis

J – Circular cutting reference for y axis

K – Circular cutting reference for z axis

G Words: - G words or codes tell the machine to perform certain functions. Most G words are modal which means they remain in effect until replaced by another modal G code.

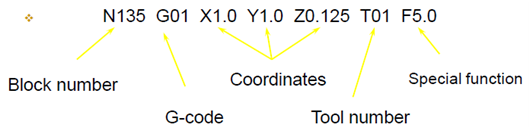

CNC Programming Basics

- CNC instructions are called part program commands.

- When running, a part program is interpreted one command line at a time until all lines are completed.

- Commands, which are also referred to as blocks, are made up of words which each begin with a letter address and end with a numerical value.

“G” AND “M” CODES

- Each letter address relates to a specific machine function. “G” and “M” letter addresses are two of the most common. A “G” letter specifies certain machine preparations such as inch or metric modes, or absolutes versus incremental modes.

- An “M” letter specifies miscellaneous machine functions and work like on/off switches for coolant flow, tool changing, or spindle rotation. Other letter addresses are used to direct a wide variety of other machine commands.

CNC programming Important things to know:-

- Coordinate System

- Units, incremental or absolute positioning

- Coordinates: X,Y,Z, A,Y,Z

- Feed rate and spindle speed

- Coolant Control: On/Off, Flood, Mist

- Tool Control: Tool and tool parameters

- Programming consists of a series of instructions in form of letter codes

- Preparatory Codes:

- G codes- Initial machining setup and establishing operating conditions

- N codes- specify program line number to executed by the MCU

- Axis Codes: X,Y,Z - Used to specify motion of the slide along X, Y, Z direction

- Feed and Speed Codes: F and S- Specify feed and spindle speed

- Tool codes: T – specify tool number

- Miscellaneous codes – M codes For coolant control and other activities

Programming Key Letters

- O - Program number (Used for program identification)

- N - Sequence number (Used for line identification)

- G - Preparatory function

- X - X axis designation

- Y - Y axis designation

- Z - Z axis designation

- R - Radius designation

- F – Feed rate designation

- S - Spindle speed designation

- H - Tool length offset designation

- D - Tool radius offset designation

- T - Tool Designation

- M - Miscellaneous function

BASIC CNC PROGRAMMING PART

COMMON G-CODES

G00 – Rapid positioning mode Tool is moved along the shortest route to programmed X,Y,Z position. Usually not used for cutting.

G01 – Linear Interpolation mode Tool is moved along a straight-line path at programmed rate of speed.

G02 – Circular motion clockwise (cw)

G03 – Circular motion counter clockwise (ccw)

G17 – XY plane

G18 – XZ plane

G19 – YZ plane

G20 – Inch Mode

G21 – Metric Mode

G28 – Return to axis machine Zero (Home)

G90 – Absolute Coordinate Reference References the next position from an absolute zero point which is set once for the entire program.

G91 – Incremental Coordinate Reference References the next position from the previous position.

G-CODES FOR CANNED CYCLES

G80 – Cancel canned cycle

G81 – Drilling cycle

G83 – Peck drilling cycle

G84 – Tapping cycle

G85 – Boring cycle

G86 – Boring cycle (NOTE: A canned cycle stays in effect until cancelled by a G80.)

G Codes: Cutter Compensation

G40 – Cancel cutter diameter compensation.

G41 – Cutter compensation left.

G42 – Cutter compensation right.

Here is the list of some G-codes which can be used as per their need

Note: - Not all the G-codes apply to each machine. And some of the G-codes can be assigned as per usage.

Some of M-codes (miscellaneous code)

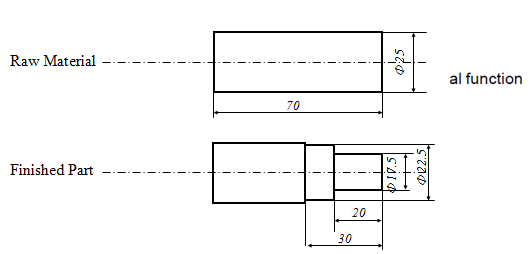

Programming Example using G-codes:-

O0013 ⇒ Program identification number

N0005 G53 ⇒To cancel any previous working zero point

N0010 T0303 ⇒ Sequence number, Tool number

N0020 G57 G00 X26.00 Z0.0 S500 M04

N0030 G01 X-0.20 F100

N0040 G00 Z2.0

N0050 X50.0 Z50.0

N0060 T0404

N0070 G57 G00 X22.50 Z2.0 S500 MAIN PROGRAM

N0080 G01 Z-30.0 F100

N0090 G00 X23.0 Z2.0 S500

N0100 G84 X17.5 Z-20.0 D0=200 D2=200 D3=650

N0110 G00 Z2.0

N0120 X50.0 Z50.0

N0130 M30 ⇒END PROGRAM

After this the work done on the work piece by the machine is

VIDEO

Category:

Comments

Nice tutorial anurag

Nice tutorial anurag

great....thanx..it helped me

thanks helping a lot